Why Are Automated Picking Robots Revolutionizing Modern Warehousing?

As the logistics industry evolves, automated picking robots are becoming more prevalent in modern warehousing. Experts like Dr. Emily Hargrave, a leading researcher in robotics, have noted, "Automated picking robots redefine warehouse efficiency." These machines navigate aisles, locate items, and fill orders faster than human workers.

In many warehouses, these robots have transformed traditional picking methods. The speed and accuracy they bring help to reduce human error and improve productivity. For example, a robot can scan and retrieve items in seconds, which is much quicker than manual labor. Yet, there are challenges; integrating these systems into existing operations can be complex.

Moreover, while automated picking robots offer numerous benefits, some workers fear job displacement. It's crucial for companies to address these concerns. Training and reskilling programs can help employees adapt to the new technology. Balancing advancements with human labor is a delicate task that requires thoughtful planning.

The Emergence of Automated Picking Robots in Warehousing

The emergence of automated picking robots is transforming modern warehousing. These robots streamline the picking process, allowing for faster and more efficient operations. They navigate aisles with precision, selecting items based on programmed criteria. This minimizes the risk of human error and speeds up order fulfillment.

Many warehouses have adopted robotic systems to handle routine tasks. These robots can operate around the clock. However, reliance on technology raises concerns. What happens if a system fails? Maintenance issues can disrupt operations. Workers may feel displaced by automation, creating a need for retraining.

Moreover, the introduction of robotics is not without setbacks. Initial costs can be high, and integration can be complex. Each warehouse has unique layouts and challenges. Finding the right robot for each environment can be challenging. The transition requires careful planning and evaluation. As technology evolves, so too will the methods we use in warehousing. Innovations will continue to reshape the landscape.

Key Technologies Driving the Efficiency of Picking Robots

Automated picking robots are transforming warehousing operations. These machines leverage advanced technologies to enhance efficiency. Key driving forces include machine learning, computer vision, and sensor technology.

Machine learning algorithms help robots learn from their environment. They adapt to new products and layouts. This adaptability reduces errors in picking. Meanwhile, computer vision allows robots to identify items accurately. This technology ensures the correct items are selected every time. It minimizes the need for human intervention.

However, challenges remain. The integration of these technologies can be complex. Not all warehouses have the infrastructure needed. Moreover, robots sometimes struggle with handling delicate items. This can lead to damage and waste. Continuous improvements are necessary to overcome these hurdles. Balancing efficiency with product safety is crucial for optimal performance.

Benefits of Automated Picking Robots in Supply Chain Operations

Automated picking robots are transforming supply chain operations with remarkable efficiency. They can handle tasks like sorting and retrieving items quickly. These robots navigate through warehouses, reducing labor costs significantly. Operations that once took hours can now be completed in minutes.

However, the integration of these systems isn't without challenges. Not every warehouse layout is suited for automation. Some environments may have narrow aisles or unpredictable stock levels. Also, the technology requires regular updates and maintenance. Despite these drawbacks, many companies see the value of investing in automation. The potential for increased accuracy and reduced errors is a compelling argument.

The speed and reliability of automated picking robots can enhance customer satisfaction. Orders are fulfilled faster and with greater precision. This shift allows human workers to focus on more complex tasks. Yet, it raises questions about workforce dynamics and job security. Adapting to this new technology requires careful planning and consideration.

Benefits of Automated Picking Robots in Supply Chain Operations

| Benefit | Description | Impact | Percentage Improvement |

|---|---|---|---|

| Increased Efficiency | Robots can handle multiple items simultaneously, reducing the time spent picking. | Speeds up order fulfillment processes. | 30% |

| Cost Reduction | Minimizes labor costs by automating repetitive tasks. | Allows reallocation of human resources to higher-value tasks. | 25% |

| Improved Accuracy | Reduces human error in picking processes. | Enhances customer satisfaction with fewer returns. | 20% |

| 24/7 Operation | Robots can operate continuously without breaks. | Maximizes warehouse output. | 40% |

| Flexibility | Easily adaptable to changing order volumes. | Handles seasonal demand fluctuations effectively. | 35% |

Challenges and Considerations in Implementing Picking Robots

Implementing automated picking robots in warehouses presents several challenges. One major concern is the initial investment. Industry reports indicate that the average cost of a robotic picking system can exceed $1 million. Many companies find it hard to justify such expenses, especially small to mid-sized operations. This figure raises questions about the return on investment, especially in fluctuating market conditions.

Training and integration issues also pose obstacles. Workers must learn to interface with the technology. Reports show that up to 30% of warehouse employees may resist this shift. They fear job displacement or are overwhelmed by new systems. The adjustment period can slow operations, negating the benefits of automation. Moreover, not all products are suitable for robotic handling, complicating the transition.

Maintenance and technical support are ongoing concerns. Robots require regular upkeep, and downtime can impact productivity. About 20% of automated systems face significant maintenance challenges within the first year of operation, based on industry statistics. Such disruptions can affect a warehouse's overall efficiency. Companies need a robust strategy to address these complexities for successful implementation.

The Future of Warehousing: Trends in Automation and Robotics

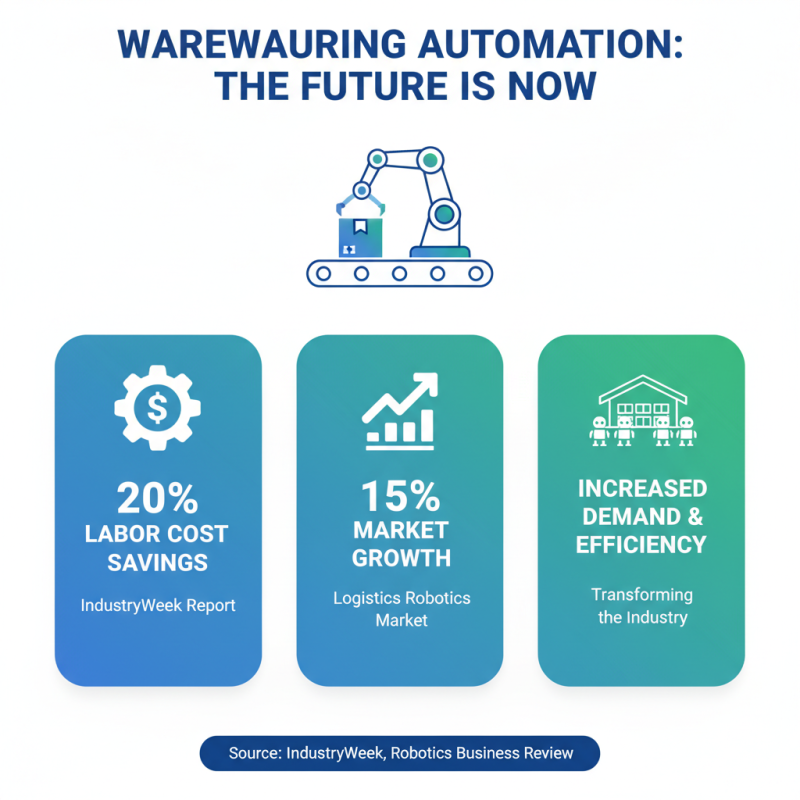

The integration of automation and robotics in warehousing is transforming the industry. In a recent report by IndustryWeek, automated systems could save companies up to 20% in labor costs. This statistic highlights the financial incentives for adoption. The logistics sector sees a surge in demand for robots, with analysts predicting a market growth rate of 15% annually over the next five years.

Robots enhance efficiency. They can manage repetitive tasks with precision. However, this shift also raises concerns. Are we losing the human touch in operations? Workers worry about job security as machines take over. A survey indicated that 57% of employees fear automation risks their roles. This dichotomy presents a challenge for leaders to balance technology and workforce needs.

Flexibility is another vital aspect. Automated systems can be programmed for various tasks but may struggle with unexpected scenarios. As per a recent McKinsey report, 30% of warehouse tasks still require human decision-making. The hybrid approach could be the answer. Combining automated processes with human oversight may lead to more robust operations, but it requires careful planning and investment.

Related Posts

-

How to Choose the Right AMR Robot for Your Business Needs

-

2025 Guide: How to Choose Between AGV and AMR for Your Warehouse Needs

-

How to Implement an Automated Guided Vehicle System in Your Warehouse Operations

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

Top 5 Picking Robots Transforming Warehouse Efficiency in 2023: Industry Insights & Data