How to Use Automated Picking Robots to Improve Warehouse Efficiency?

In today's fast-paced logistics environment, companies seek innovative ways to enhance warehouse operations. Automated picking robots have emerged as a transformative solution. These robots significantly reduce picking times and minimize human error. Expert Anna Roberts, a leader in warehouse automation, once stated, "Automated picking robots will redefine efficiency in logistics."

Imagine a warehouse where robots navigate seamlessly, selecting items with precision. Each robot can pick and transport multiple items at once, streamlining the entire process. However, the transition to this technology is not without challenges. Businesses must integrate these systems with existing workflows, which can be complex. Some workers may also feel uneasy about automation replacing jobs.

Embracing automated picking robots requires careful planning and investment. Warehouse managers must understand both the benefits and the potential disruptions. As more organizations adopt this technology, ongoing discussions about its impact will become crucial. Balancing efficiency with workforce adaptation remains a key concern in this evolving landscape.

Understanding Automated Picking Robots in Warehousing

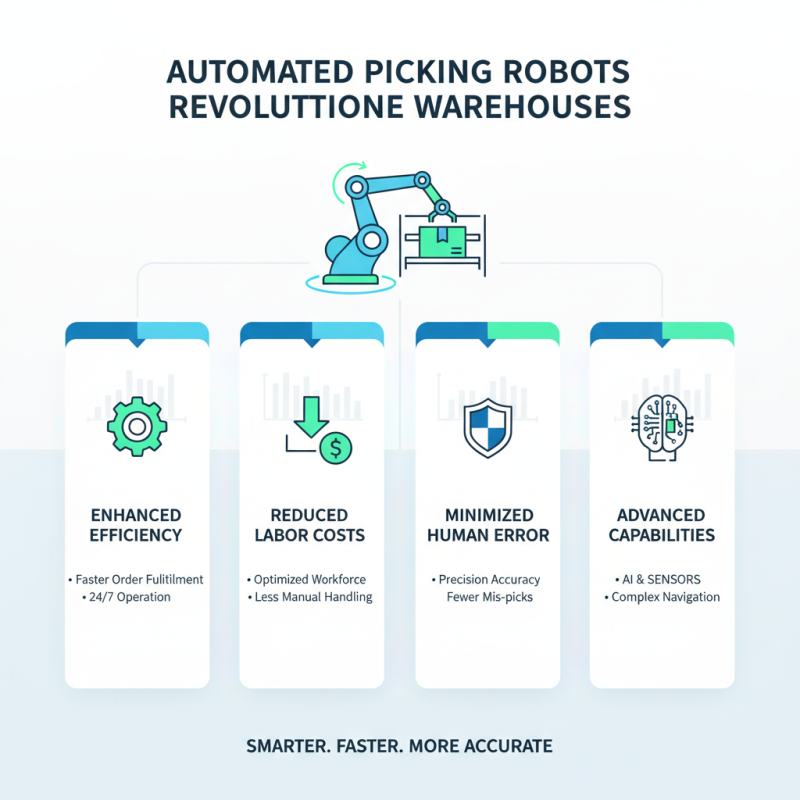

Automated picking robots are revolutionizing warehousing. They streamline operations, boost accuracy, and reduce labor costs. These robots can work tirelessly, navigating aisles and picking items with precision. They analyze inventory data in real-time, ensuring the correct items are picked quickly.

Tips: Assess your storage layout before implementing robots. A well-organized warehouse maximizes efficiency. Consider the types of items you store. Larger items may require different handling than smaller ones.

While the benefits are clear, some challenges persist. Not all robots can adapt to existing workflows. Training staff to work alongside robots is crucial. Effective communication between humans and machines can enhance performance.

Tips: Start small when integrating robots. Test them in one area before a full rollout. This allows you to identify issues early on and assess their impact on productivity. Continuous evaluation of performance and adaptability is essential for long-term success.

Automated Picking Robots Impact on Warehouse Efficiency

Benefits of Implementing Automated Picking Robots

Automated picking robots have revolutionized warehouse operations. These machines enhance efficiency, reduce labor costs, and minimize human error. With advanced sensors and AI, they navigate complex environments, locating items quickly. This accuracy means faster order fulfillment, which is crucial for customer satisfaction.

Implementing automated picking robots can lead to significant benefits. For instance, they can work around the clock, increasing productivity. However, the integration process can be challenging. Staff may resist new technology, feeling uncertain about their roles. Additionally, maintenance of robotic systems requires expertise. Ensuring reliable performance is essential for maximizing benefits.

Many warehouses still rely on traditional methods. This may seem easier, but it often leads to delays and inaccuracies. Companies need to assess their current systems critically. Balancing human and robotic workforce is a common dilemma. Evaluating each aspect carefully can lead to better decisions in automation. Integrating new technologies takes time, but the potential rewards can be substantial.

Integrating Robots with Warehouse Management Systems

Integrating automated picking robots with warehouse management systems (WMS) can streamline operations significantly. These robots enhance accuracy by minimizing human errors during item selection. Real-time data exchange between robots and the WMS is vital. It provides updates on inventory levels, helping in better stock management. The challenge, however, lies in ensuring compatibility between varied systems and robotic technology.

Data synchronization is crucial for successful integration. If the systems do not communicate seamlessly, delays and confusion can arise. Workers may struggle to adapt to new processes. Training is essential to maximize efficiency. Robots can function better when staff understands their operations. Identifying these gaps in training is important for improvement.

Regular assessments of the integration process are necessary. As robots operate, technical issues may develop. Delays can impact overall efficiency if not addressed quickly. Collecting feedback from workers helps identify ongoing challenges. This feedback loop can enhance the integration process over time. Balancing technology and human insight is key to optimizing warehouse performance.

How to Use Automated Picking Robots to Improve Warehouse Efficiency? - Integrating Robots with Warehouse Management Systems

| Warehouse Area (sq ft) | Number of Robots | Picking Rate (items/hour) | Error Rate (%) | Order Fulfillment Time (min) |

|---|---|---|---|---|

| 50,000 | 10 | 300 | 1.5 | 15 |

| 75,000 | 15 | 450 | 1.2 | 12 |

| 100,000 | 20 | 600 | 1.0 | 10 |

| 120,000 | 25 | 750 | 0.8 | 8 |

Best Practices for Optimizing Robot Efficiency

Automated picking robots can significantly boost warehouse efficiency. However, it's crucial to optimize their performance. Adjusting robot speed is a good start. If they move too fast, they might miss items or cause accidents. Slower speeds can improve accuracy but may slow down operations.

In addition, the layout of the warehouse plays a vital role. Organizing items strategically can minimize travel time. Robots should always have clear paths. This reduces the chance of collisions and improves pick times. Regular assessments are needed. Are robots encountering obstacles? Are they frequently stopping? Such information is essential for ongoing improvements.

Another aspect is inventory management. Keeping accurate stock levels ensures robots don't waste time searching for out-of-stock items. Implementing a robust inventory system can help optimize this process. Yet, monitoring the robots themselves can also be overlooked. Regular maintenance checks should be scheduled. This prevents unexpected breakdowns that can disrupt workflow. Optimizing robot efficiency requires constant reflection and adjustment.

Measuring the Impact of Robots on Warehouse Performance

The impact of automated picking robots on warehouse performance is significant.

Robots can handle tasks with precision. They reduce the time taken to pick items. This leads to faster order fulfillment. By measuring efficiency, managers can pinpoint areas needing improvement.

Robotics can decrease human error, but they are not flawless.

Sometimes, the robots face challenges navigating narrow aisles.

Evaluating performance metrics is crucial.

Key indicators include speed, accuracy, and employee satisfaction. Increased speed often results in higher throughput. However, workers might feel uneasy with robots around.

Training staff to work alongside these machines is essential. Communication becomes vital to avoid conflicts. Robots may sometimes require adjustments. Their programming needs ongoing evaluation to ensure optimal functioning.

Analyzing data collected from robot operations helps refine processes.

This analysis can reveal trends over time. In some cases, the introduction of robots may disrupt existing workflows. Reflection on these disruptions can lead to new strategies. Continuous improvement is the goal.

Balancing technology and human input is important for warehouse success.

Related Posts

-

Top 5 Picking Robots Transforming Warehouse Efficiency in 2023: Industry Insights & Data

-

How to Choose the Right AMR Robot for Your Business Needs

-

2025 Guide: How to Choose Between AGV and AMR for Your Warehouse Needs

-

How to Choose an Automated Material Handling System in 2026?

-

Top Trends in Automated Guided Vehicle System Technology Unveiled?

-

Why Are Automated Picking Robots Revolutionizing Modern Warehousing?